Ubushinwa 6 Axis 1800mm Ukuboko kugera kuri Automatic Steel MIG Welding Robotic Arm

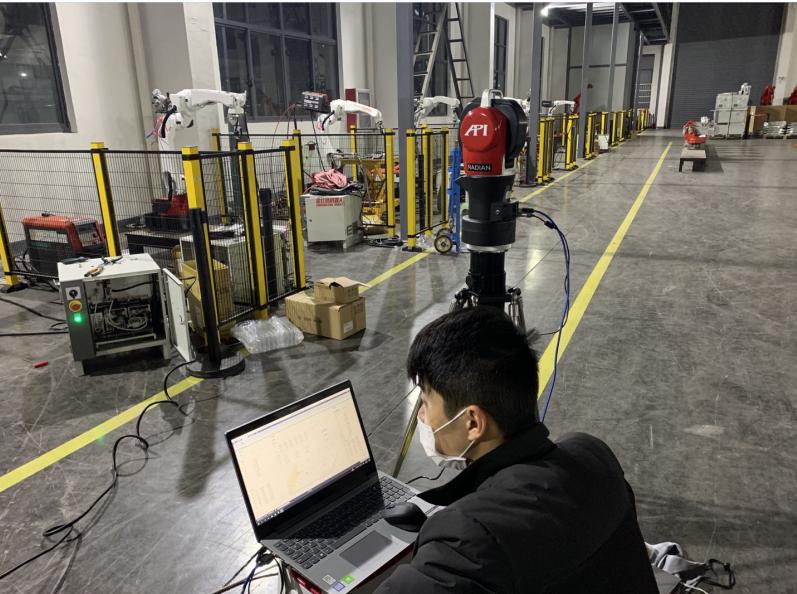

LASER CALIBRATION IKIZAMINI CY'IKIZAMINI CYIZA

JHY ikoresha uburyo bwa kalibibasi ya laser kugirango igerageze gusubiramo umwanya wa robo.Nyuma y ibizamini byinshi, gusubiramo umwanya wa robo yacu irarenze cyane ± 0.08mm.

Koresha AMAFARANGA YISUMBUYE KUBIKORWA BY'INGENZI

Ibikoresho byingenzi bya robo nka moteri ya servo, kugabanya RV, kugabanya imiterere, kugabanya servo nibindi byose bakoresha ibirango byo hejuru mubushinwa, byageragejwe no gukoresha igihe kirekire kugirango tumenye neza ko bikwiriye robot yacu.

GUKURIKIRA BYOROSHE

Kubungabunga biroroshye, Ukurikije ubuyobozi bwo kubungabunga bwatanzwe natwe abakiriya ubwabo barashobora gukora byoroshye.

NYUMA YO KUGURISHA

Buri mukiriya afite itsinda ryayo nyuma yo kugurisha.Niba ukeneye ubufasha nyuma yo kugurisha, Pls ubaze igihe icyo aricyo cyose.Ba injeniyeri bacu babigize umwuga bazabikemura mugihe gito.Ingingo ni ubuntu.

| Ibipimo byo gusudira byerekana ibyuma byoroheje hamwe nicyuma gito | |||||||||

| Ubwoko | isahani | Diameter | icyuho | gusudira | gusudira | umuvuduko wo gusudira | Menyesha inama-akazi | Gazi itemba | Inguni yo gusudira |

| Gusudira T-gusudira | 1.0 | 0.8 | 2.5 ~ 3 | 70 ~ 80 | 17 ~ 18 | 8 ~ 10 | 10 | 10 ~ 15 | 45 ° |

| 1.2 | 1.0 | 3 ~ 3.5 | 85 ~ 90 | 18 ~ 19 | 8 ~ 10 | 10 | 10 ~ 15 | 45 ° | |

| 1.6 | 1.0,1.2 | 3 ~ 3.5 | 100 ~ 110 | 18 ~ 19.5 | 8 ~ 10 | 10 | 10 ~ 15 | 45 ° | |

| 2.0 | 1.0,1.2 | 3 ~ 3.5 | 115 ~ 125 | 19.5 ~ 20 | 8 ~ 10 | 10 | 10 ~ 15 | 45 ° | |

| 2.3 | 1.0,1.2 | 3 ~ 3.5 | 130 ~ 140 | 19.5 ~ 21 | 8 ~ 10 | 10 | 10 ~ 15 | 45 ° | |

| 3.2 | 1.0,1.2 | 3.5 ~ 4 | 150 ~ 170 | 21 ~ 22 | 7.5 ~ 8 | 15 | 15 ~ 20 | 45 ° | |

| 4.5 | 1.0,1.2 | 4.5 ~ 5 | 180 ~ 220 | 21 ~ 23 | 6.5 ~ 7.5 | 15 | 15 ~ 20 | 45 ° | |

| 1.2 | 5 ~ 5.5 | 200 ~ 250 | 24 ~ 26 | 6.5 ~ 8 | 10 ~ 15 | 10 ~ 20 | 45 ° | ||

| 6 | 1.2 | 5 ~ 5.5 | 230 ~ 260 | 25 ~ 27 | 6.5 ~ 7.5 | 20 | 15 ~ 20 | 45 ° | |

| 6 | 220 ~ 250 | 25 ~ 27 | 5.5 ~ 7.5 | 13 ~ 18 | 10 ~ 20 | 45 ° | |||

| 4 ~ 4.5 | 270 ~ 300 | 28 ~ 31 | 10 ~ 11.5 | 13 ~ 18 | 10 ~ 20 | 45 ° | |||

| 8,9 | 1.2,1.6 | 6 ~ 7 | 270 ~ 380 | 29 ~ 35 | 6.5 ~ 7.5 | 25 | 20 ~ 25 | 50 ° | |

| 8 | 1.2 | 5 ~ 6 | 270 ~ 300 | 28 ~ 31 | 9 ~ 10 | 13 ~ 18 | 10 ~ 20 | 45 ° | |

| 1.2 | 7 ~ 8 | 260 ~ 300 | 26 ~ 32 | 4 ~ 5.5 | 15 ~ 20 | 10 ~ 20 | 50 ° | ||

| 1.6 | 6.5 ~ 7 | 300 ~ 330 | 30 ~ 34 | 5 ~ 5.5 | 15 ~ 20 | 10 ~ 20 | 50 ° | ||

| 12 | 1.2,1.6 | 7 ~ 8 | 270 ~ 380 | 27 ~ 35 | 4.5 ~ 6.5 | 20 ~ 25 | 20 ~ 25 | 50 ° | |

| 1.2 | 7 ~ 8 | 260 ~ 300 | 26 ~ 32 | 4 ~ 5.5 | 15 ~ 20 | 10 ~ 20 | 50 ° | ||

| 1.6 | 6.5 ~ 7 | 300 ~ 330 | 30 ~ 34 | 5 ~ 6 | 15 ~ 20 | 10 ~ 20 | 50 ° | ||

Icyitonderwa:

1. Gusudira MIG ikoresha gaze ya inert, ikoreshwa cyane cyane mu gusudira aluminiyumu hamwe n’ibisigazwa byayo, umuringa hamwe n’ibisigazwa byayo, titanium hamwe n’ibisigazwa byayo, hamwe n’ibyuma bitagira umwanda hamwe n’ibyuma birwanya ubushyuhe.MAG gusudira hamwe na gaze ya gaze ya CO2 ikoreshwa cyane cyane mu gusudira ibyuma bya karubone hamwe nicyuma gito cyane.

2. Ibirimo byavuzwe haruguru nibyerekanwe gusa, kandi nibyiza kubona ibipimo byiza byo gusudira hakoreshejwe igeragezwa.Diameter ya wire yavuzwe haruguru ishingiye kubintu bifatika.